| << Chapter < Page | Chapter >> Page > |

The study of electrostatics has proven useful in many areas. This module covers just a few of the many applications of electrostatics.

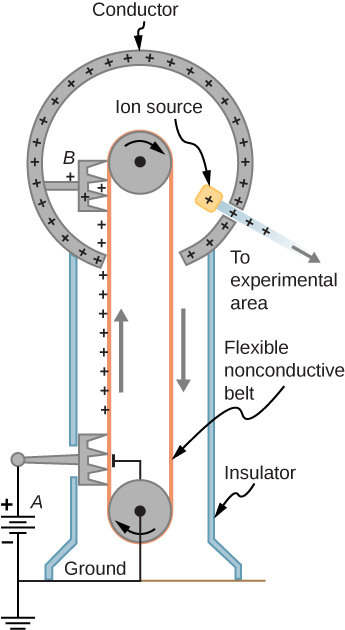

Van de Graaff generator s (or Van de Graaffs) are not only spectacular devices used to demonstrate high voltage due to static electricity—they are also used for serious research. The first was built by Robert Van de Graaff in 1931 (based on original suggestions by Lord Kelvin) for use in nuclear physics research. [link] shows a schematic of a large research version. Van de Graaffs use both smooth and pointed surfaces, and conductors and insulators to generate large static charges and, hence, large voltages.

A very large excess charge can be deposited on the sphere because it moves quickly to the outer surface. Practical limits arise because the large electric fields polarize and eventually ionize surrounding materials, creating free charges that neutralize excess charge or allow it to escape. Nevertheless, voltages of 15 million volts are well within practical limits.

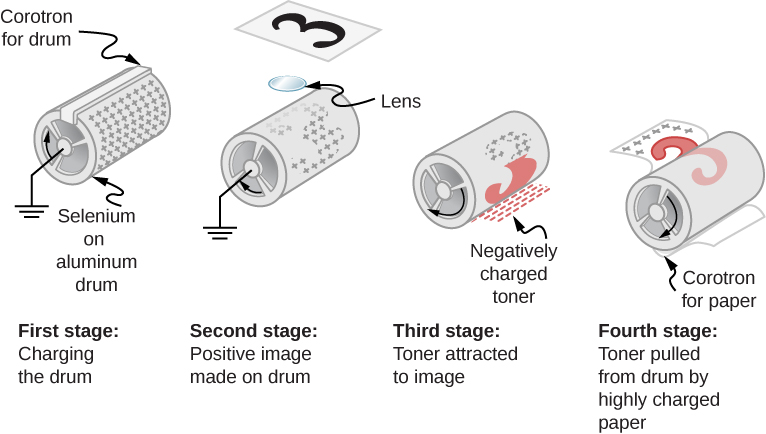

Most copy machines use an electrostatic process called xerography —a word coined from the Greek words xeros for dry and graphos for writing. The heart of the process is shown in simplified form in [link] .

A selenium-coated aluminum drum is sprayed with positive charge from points on a device called a corotron. Selenium is a substance with an interesting property—it is a photoconductor . That is, selenium is an insulator when in the dark and a conductor when exposed to light.

In the first stage of the xerography process, the conducting aluminum drum is grounded so that a negative charge is induced under the thin layer of uniformly positively charged selenium. In the second stage, the surface of the drum is exposed to the image of whatever is to be copied. In locations where the image is light, the selenium becomes conducting, and the positive charge is neutralized. In dark areas, the positive charge remains, so the image has been transferred to the drum.

Notification Switch

Would you like to follow the 'University physics volume 2' conversation and receive update notifications?