| << Chapter < Page | Chapter >> Page > |

In this case, an interrupt is programmed which tells the device to sample the input from the FSR and UGB network, convert it to digital, and update the LCD with the new information. This interrupt occurs one time per second. What this means is that the sensor is sampled and the LCD is updated only once per second. After the sampling, control is handed back to the loop until the next interrupt occurs.

Inside the microprocessor the instantaneous value of the analog signal is converted into a digital value and stored under a previously declared floating point variable. The following equation is used to calculate the actual weight in grams of the object on the sensor. The data is displayed on the LCD.

![]()

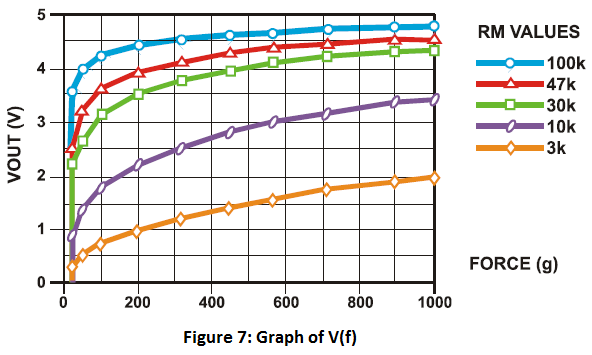

In the equation, “y” equals the weight in grams and “x” is the value stored under the floating point variable that is representative of the analog signal present on the microprocessor’s input pin. This equation was derived from the specifications sheet of the FSR when using a ten kilo-ohm resistor (See figure seven, use the purple plot). Using a different resistor might have allowed the use of a simpler equation. Bear in mind however that the rail voltage to the UGB was only 3.3 volts. This was necessary because 3.3 volts was the max allowable input to the microprocessor. The 10 kilo-ohm resistor yields a maximum output very close to 3.3 volts and was thus ideal.

Because the equation is cumbersome it takes the microprocessor some time to crunch the numbers. Mike Toth suspected that this is the cause of the flickering on the LCD. It turns out that the microprocessor we used is better suited for solving linear or quadratic equations in any efficient manner.

What we have described is the inner workings of a device that can sense and output the magnitude of a force applied to its sensing element. The range of the device is between zero and 890 grams. Ideally the device should take measurements up to 1000 grams however the UGB becomes saturated before that is allowed to occur. The device is not terribly accurate but definitely can be used to get the sense that a force is being applied to the FSR. Some of the ways that accuracy can be improved are as follows. Firstly, we could invest in a more expensive sensor (we bought ours for $7.95). Secondly, we could do more testing to fine tune the equation used in the calculation. A piecewise continuous function might be more suitable. Finally, one of the main flaws in the device is the fact that pressure is not evenly applied across the entire sensing area. Some type of mechanism that evenly distributes the weight across the FSR is sure to boost the accuracy of the device (see figure 8).

There are many different applications for force sensors that function in a manner similar to ours. The first one that comes to mind is the scale. The compact, rugged, and inexpensive nature of our sensor lends itself very well to those small digital scales used for weighing food portions. The only issue with the scale is that usually a high degree of accuracy is expected. Assuming we can correct that about our device a scale would be a perfect application for our creation. In all branches of engineering smart applications are the ways of the future. Force sensors can be a part of many different types of “smart” infrastructure. Roads and bridges are great places to incorporate force sensors. Transportation engineers could use them to gauge strain on roadways and electrical engineers could incorporate them into the design of the new red light camera systems that are coming our way soon. If they were only activated as car approaches their efficiency in terms of tickets per kilo-joule could be increased. In the near future force sensors may find their way into advanced applications such as robotics. Japan is the world leader in developing human like robots called androids. One of the more difficult tasks in mimicking human behavior is the act of walking. Most walking robots today have flat feet and lack the grace that humans have as they glide across a room. Instead they kind of lumber along. Force sensors could be a key element in developing a life-like walking android. Think about all of the nerve endings we have in our toes and feet that help us walk without any real effort. To conclude, this has been an excellent first opportunity to explore the possibilities that modern electronics has to offer. We look forward to taking it to the next level and one day implementing such technology in the field!

[1]

(External Link)

[2]

(External Link)

[3]

(External Link)

[4]

(External Link)

Notification Switch

Would you like to follow the 'Eel3111 force sensor group july 2010' conversation and receive update notifications?