| << Chapter < Page | Chapter >> Page > |

| Human Health (cancer) | Kg Benzene eq/unit |

|---|---|

| Human Health (non-cancer) | LC 50 eq from exposure modeling |

| Global Climate Change | Kg CO 2 eq/unit |

| Eutrophication | Kg Nitrogen eq/unit |

| EcotoxicityAquatic, Terrestrial Toxicity | Kg 2,4 D eq/unitLC 50 eq from exposure modeling |

| Acidification | Kg H + /unit |

| Smog Formation | Kg Ethane eq/unit |

| Stratospheric Ozone Depletion | Kg CFC-11 eq/unit |

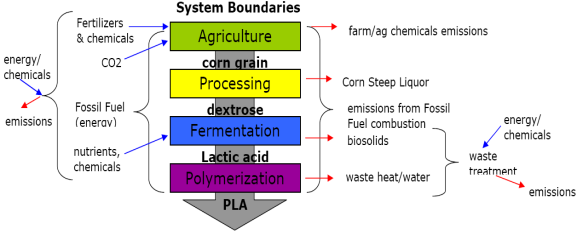

An example will help to illustrate the type of information that results from life cycle inventory and impact assessments. In this case, a system that produces a biologically-derived plastic, polylactide, is examined. (PLA) . PLA has been proposed as a more sustainable alternative to plastics produced from petroleum because it is made from plant materials, in this case corn, yet has properties that are similar to plastics made from petroleum. Figure Processing Diagram for Making Polylactide shows a schematic of the system, which is a cradle-to-gate assessment. As with any plastic, PLA can be turned into a variety of final products and each will have different cradle-to-grave LCA characteristics. The production of PLA involves growing corn, harvesting and processing the grain, and polymerizing the lactic acid molecules produced from fermentation. At each step a variety of chemicals and energy are used or produced. It is these production materials that contribute to the impact analysis. Inventory quantities were allocated among major bio-products on a mass basis.

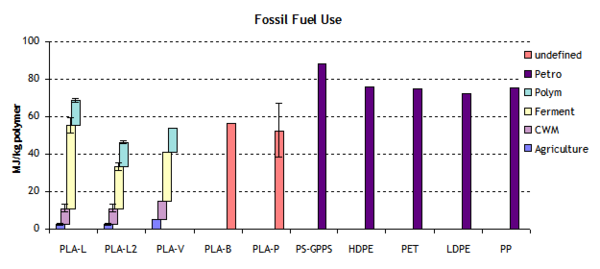

Among the inventory data acquired in this case is life cycle fossil fuel used by the system, mostly to power farming equipment (“Agriculture”), wet-mill corn (“CWM”), heat fermentation vats (“Ferment”), and Polymerization (“Polym”). The transport of intermediate products from sources to the processing center is also included. Figure Fossil Fuel Use to Make PLA vs. Petroleum-Based Plastics shows the fossil fuel used to make PLA compared with fossil fuel used for making several petroleum-based plastics. Figure Global Warming Potential Impact Analysis shows the global warming potential impact analysis. As might have been expected, the fossil fuels used to make PLA are slightly less than for the petroleum-derived plastics on an

Notification Switch

Would you like to follow the 'Sustainability: a comprehensive foundation' conversation and receive update notifications?