| << Chapter < Page | Chapter >> Page > |

Plasmas are generated for a variety of thin film processes including sputtering, etching, ashing, and plasma-enhanced CVD. Plasma-enhanced CVD (PECVD), sometimes called plasma-assisted (PACVD), has the advantage that plasma activated reactions occur at much lower temperatures compared to those in thermal CVD. For example, the thermal CVD of silicon nitride occurs between 700 - 900 °C, the equivalent PECVD process is accomplished between 250 - 350 °C.

A plasma is a partially ionized gas consisting of electrons and ions. Typical ionization fractions of 10 -5 to 10 -1 are encountered in process reactors. Plasmas are electrically conductive with the primary charge carriers being the electrons. The light mass of the electron allows it to respond much more quickly to changes in the field than the heavier ions. Most plasmas used for PECVD are generated using a rf electric field. In the high frequency electric field, the light electrons are quickly accelerated by the field but do not increase the temperature of the plasma because of their low mass. The heavy ions cannot respond to the quick changes in direction and therefore their temperature stays low. Electron energies in the plasma have a Maxwellian distribution in the 0.1 – 20 eV range. These energies are sufficiently high to excite molecules or break chemical bonds in collisions between electrons and gas molecules. The high energy electrons inelastically collide with gas molecules resulting in excitation or ionization. The reactive species generated by the collisions do not have the energy barriers to reactions that the parent precursors do. Therefore, the reactive ions are able to form films at temperatures much lower than those required for thermal CVD.

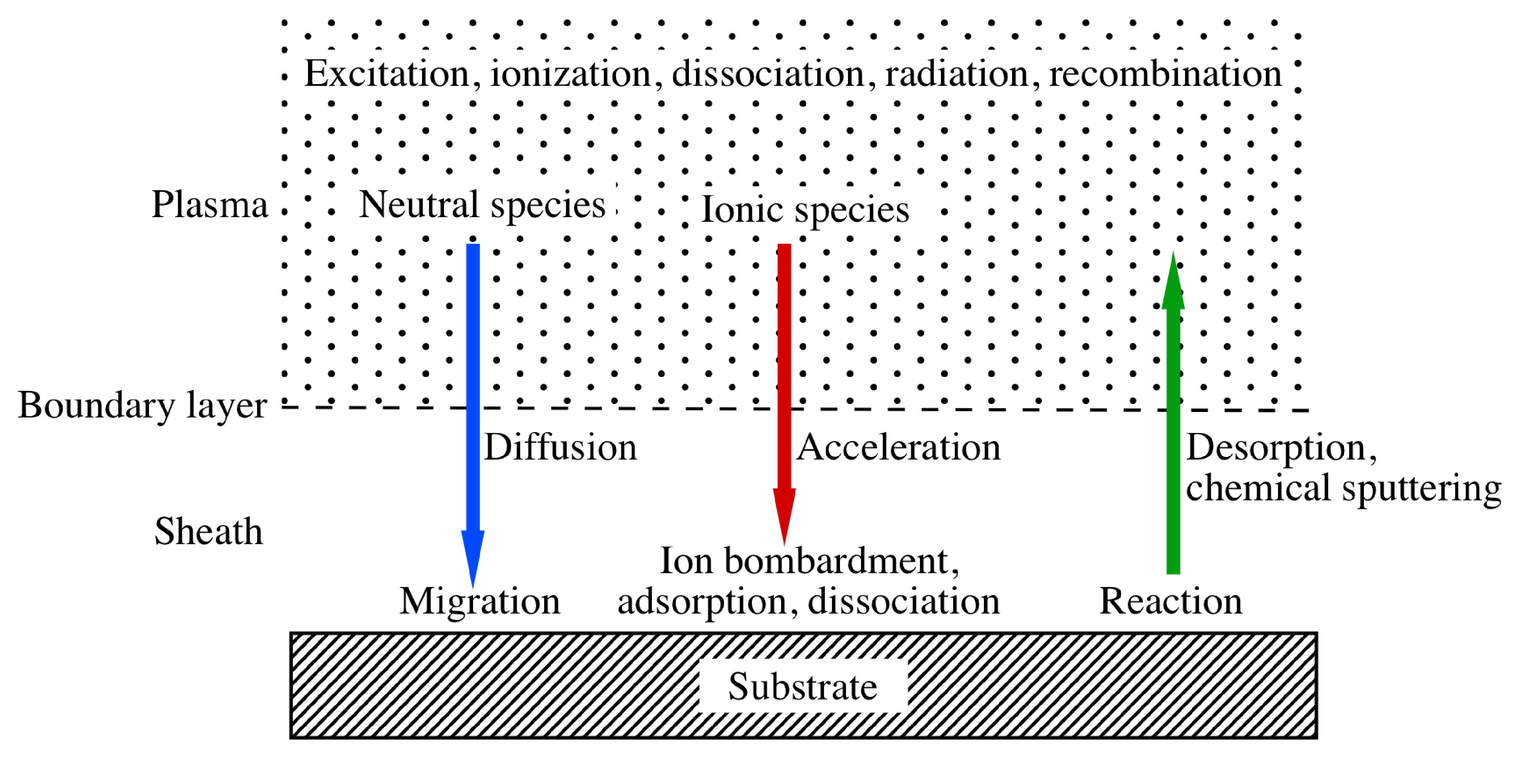

The general reaction sequence for PECVD is shown in [link] . In addition to the processes that occur in thermal CVD, reactive species resulting from electron dissociation of parent molecules also diffuse to the surface. The reactive species have lower activation energies for chemical reactions and usually have higher sticking coefficients to the substrate. Therefore, the PECVD reaction is dominated by the reactive species on the surface and not any of the the parent precursor molecules that also diffuse to the surface.

A basic PECVD reactor is shown in [link] . The wafer chuck acts as the lower electrode and is normally placed at ground potential. Gases are either introduced radially at the edges of the reactor and pumped out from the center, or gases can be introduced from the center and pumped at the edges as shown in [link] . The magnetic drive allows rotation of the wafers during processing to randomize substrate position. Some newer reactors introduce the gases through holes drilled in the upper electrode. This method of gas introduction gives a more uniform plasma distribution.

Notification Switch

Would you like to follow the 'Chemistry of electronic materials' conversation and receive update notifications?