| << Chapter < Page | Chapter >> Page > |

It has long been known that nitrogen and hydrogen react to form ammonia. However, it became possible to manufacture ammonia in useful quantities by the reaction of nitrogen and hydrogen only in the early 20th century after the factors that influence its equilibrium were understood.

To be practical, an industrial process must give a large yield of product relatively quickly. One way to increase the yield of ammonia is to increase the pressure on the system in which N 2 , H 2 , and NH 3 are at equilibrium or are coming to equilibrium.

The formation of additional amounts of ammonia reduces the total pressure exerted by the system and somewhat reduces the stress of the increased pressure.

Although increasing the pressure of a mixture of N 2 , H 2 , and NH 3 will increase the yield of ammonia, at low temperatures, the rate of formation of ammonia is slow. At room temperature, for example, the reaction is so slow that if we prepared a mixture of N 2 and H 2 , no detectable amount of ammonia would form during our lifetime. The formation of ammonia from hydrogen and nitrogen is an exothermic process:

Thus, increasing the temperature to increase the rate lowers the yield. If we lower the temperature to shift the equilibrium to favor the formation of more ammonia, equilibrium is reached more slowly because of the large decrease of reaction rate with decreasing temperature.

Part of the rate of formation lost by operating at lower temperatures can be recovered by using a catalyst. The net effect of the catalyst on the reaction is to cause equilibrium to be reached more rapidly.

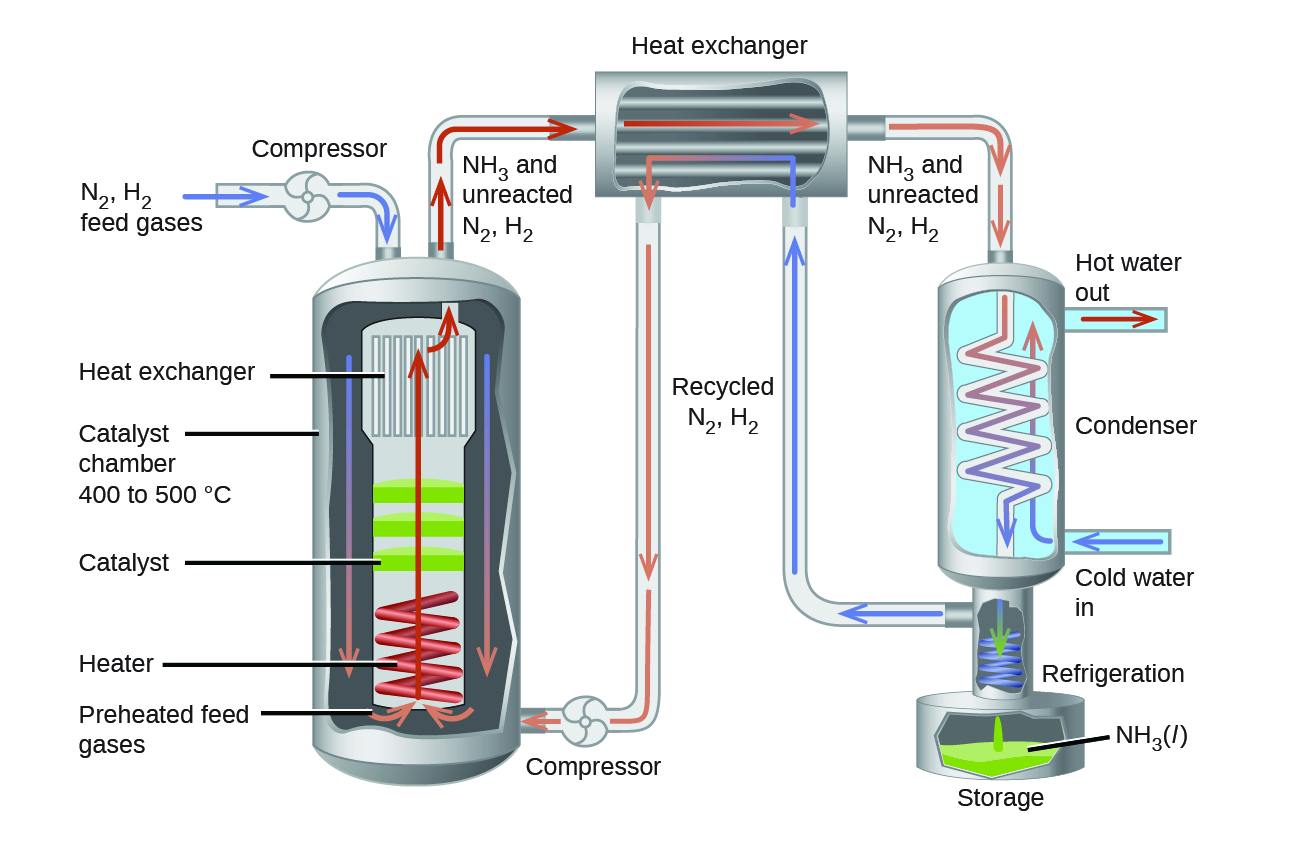

In the commercial production of ammonia, conditions of about 500 °C, 150–900 atm, and the presence of a catalyst are used to give the best compromise among rate, yield, and the cost of the equipment necessary to produce and contain high-pressure gases at high temperatures ( [link] ).

Systems at equilibrium can be disturbed by changes to temperature, concentration, and, in some cases, volume and pressure; volume and pressure changes will disturb equilibrium if the number of moles of gas is different on the reactant and product sides of the reaction. The system's response to these disturbances is described by Le Châtelier's principle: The system will respond in a way that counteracts the disturbance. Not all changes to the system result in a disturbance of the equilibrium. Adding a catalyst affects the rates of the reactions but does not alter the equilibrium, and changing pressure or volume will not significantly disturb systems with no gases or with equal numbers of moles of gas on the reactant and product side.

| Effects of Disturbances of Equilibrium and K | |||

|---|---|---|---|

| Disturbance | Observed Change as Equilibrium is Restored | Direction of Shift | Effect on K |

| reactant added | added reactant is partially consumed | toward products | none |

| product added | added product is partially consumed | toward reactants | none |

| decrease in volume/increase in gas pressure | pressure decreases | toward side with fewer moles of gas | none |

| increase in volume/decrease in gas pressure | pressure increases | toward side with more moles of gas | none |

| temperature increase | heat is absorbed | toward products for endothermic, toward reactants for exothermic | changes |

| temperature decrease | heat is given off | toward reactants for endothermic, toward products for exothermic | changes |

Notification Switch

Would you like to follow the 'Chemistry' conversation and receive update notifications?